New vacuum chamber press and integrated processes: Becker&Müller deepens its capabilities in multilayer production

The number of multilayers produced reads like a consistent response to technological progress: constant growth rates in the high multi-digit percentage range have been recorded here in recent years. In addition, there are new special applications for special types of PCB. As a manufacturer of such sophisticated multilayer printed circuit boards, we are a direct part of this development. We are now expanding our production capacities with a new heating press, thus breaking new ground in the direction of connectivity and process optimization – with benefits for employees and customers.

Heat up strongly, let cool down in a controlled manner: What sounds simple is in practice a very demanding process. Multilayers consist of up to 24 layers with structured conductive tracks, each separated by so-called prepregs. The term refers to a resin-impregnated glass fabric that is pre-cured but not cured. During the pressing process, the prepregs flow and solidify, thereby bonding the layers together and serving as an insulator between the layered conductor patterns. To ensure a defined condition of the multilayers, specified parameters must be strictly adhered to in the automated process. Pressing force, temperature, vacuum and their timing are specified by the suppliers of the base material. In combination with Becker&Müller’s many years of experience, this is used to create the process data set (the so-called “recipe”) individually for all materials and panel sizes. The standard procedure provides for a process run of the multilayers in the heating press, followed by defined cooling under maintained pressing force in the cooling press. In addition to standard PCBs, the focus at Becker&Müller is increasingly on special types for special applications, reveals Janik Becker: “For example, a customer needs PCBs for his special application on which solid ceramic blocks are pressed for thermal shielding. Of course, this is not done in the standard process.”

The downstream cooling process in particular always presents a challenge – technologically and in terms of production. “Heating and cooling presses must be optimally coordinated in terms of timing, and waiting time to reach different starting temperatures should also be avoided,” explains Janik Becker. As managing director of the experienced family-owned company, he and his team have in-depth expertise in multilayer production. “Our new heating press is a response to increased volume requirements, but also an important building block in the future orientation of our process infrastructure.”

The new LP125-2-VK vacuum chamber press from HML Haseneder Maschinenbau e.K. is the second of its kind at Becker&Müller. Complementing the existing HML heating and cooling press, it increases productivity by at least double. Formats up to 540 x 650 mm can be pressed in two press chambers, with a pressing force of 4 to 125 tons (40 – 1,250kN). The loaded press packs each hold several m² of panels of identical base material per chamber. “Previously, this was exactly our bottleneck,” clarifies the managing director. “With the new line, we have been able to increase our capacities by more than 100% – and still have room for improvement.” Increased pressure accuracy including temperature control ensures that all parameters are always in view and are recorded without gaps. “This continuous traceability is also a strong argument for our customers,” Becker lets us know. An equally strong argument for the environment of the electrically heated and water-cooled press: The heated cooling water is used to heat the company’s own premises by means of heat recovery – for added sustainability.

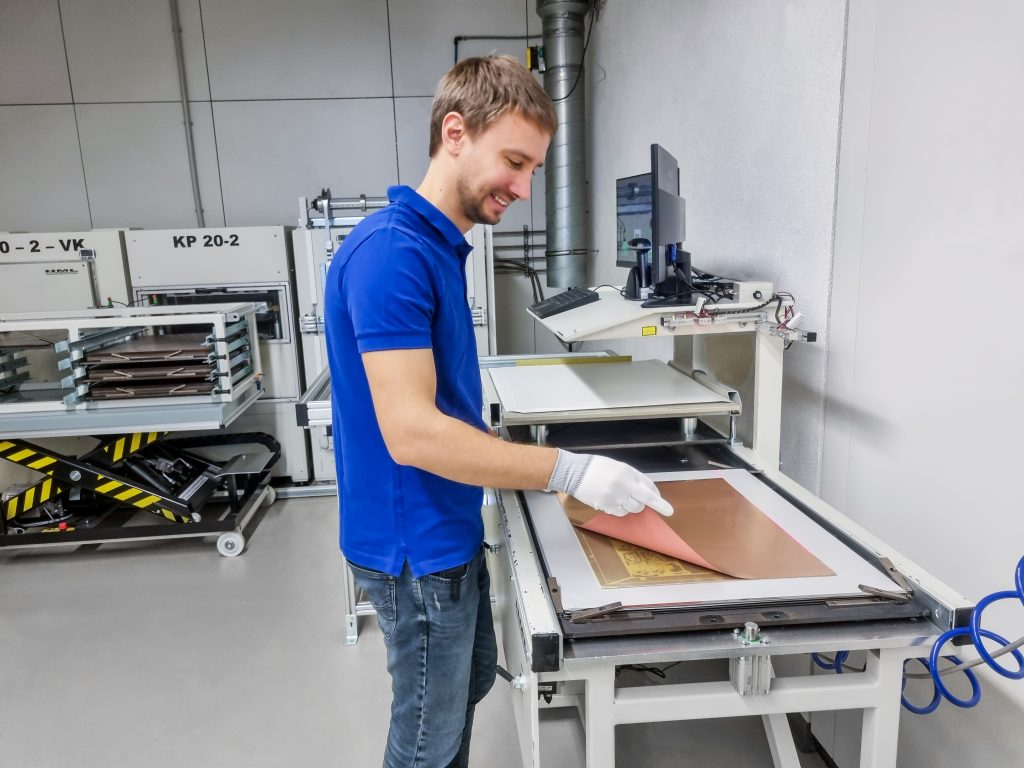

With the integration of the new heating press, the production processes were also realigned. One of the central factors in this process optimization of multilayer production at Becker&Müller is a new handling system. This is used to transport the multilayers from the layering station to the presses. With eight compartments for press packs, this not only offers more capacity, but is now also integrated into intelligent processes, for example by automatically approaching the press chambers.

For this purpose, a new, completely integrated control system for the entire multilayer production process has been introduced. Instead of a separate control system for each press, as was previously the case, all three are controlled via a central control system. “The end-to-end connectivity makes us faster and increases our process reliability. The press capacity can be adapted precisely and just-in-sequence to the capacity of the manual layering of the multilayers as well as the availability of the cooling press, waiting times are eliminated. This means, for example, that we can keep packages at a constant temperature in the heating press until the cooling press is free,” says Becker. “In addition, human error is minimized and overall handling is simplified. The efficient layout within our infrastructure allows us to achieve a significantly higher level of performance with smaller spatial dimensions.”

Another advantage of process automation is that the final pressings, including the heating and cooling process, can run automatically after the end of the shift. “The next morning, we can then start drilling the multilayers right away. The interaction of the three presses with the drilling machines, which also work autonomously in the ghost shift, makes it possible to minimize WIP or delivery times.”

Anyone who thought that the new automated processes at Becker&Müller would now make employees superfluous is proven wrong. “The opposite is the case,” Janik Becker is pleased to report. “Thanks to the new curing press, along with the increased connectivity, we can produce faster and therefore more – which also means more work in upstream and downstream processes. For this reason, we even had to double our staff in the area of multilayer production.”

Another interesting detail that says a lot about the company’s philosophy is that the temperature spectrum of the new line extends up to 400°C: “Actually, that’s much more than necessary,” explains Janik Becker. “For pressing multilayers, a temperature range of up to 300°C is usually sufficient. However, we deliberately want to keep all options open for the future, for example for special materials or new processes – in other words, precisely the special solutions for which we at Becker&Müller have been known for many years.”

The number of multilayers produced reads like a consistent response to technological progress: constant growth rates in the high multi-digit percentage range have been recorded here in recent years. In addition, there are new special applications for special types of PCB. As a manufacturer of such sophisticated multilayer printed circuit boards, we are a direct part of this development. We are now expanding our production capacities with a new heating press, thus breaking new ground in the direction of connectivity and process optimization – with benefits for employees and customers.

Heat up strongly, let cool down in a controlled manner: What sounds simple is in practice a very demanding process. Multilayers consist of up to 24 layers with structured conductive tracks, each separated by so-called prepregs. The term refers to a resin-impregnated glass fabric that is pre-cured but not cured. During the pressing process, the prepregs flow and solidify, thereby bonding the layers together and serving as an insulator between the layered conductor patterns. To ensure a defined condition of the multilayers, specified parameters must be strictly adhered to in the automated process. Pressing force, temperature, vacuum and their timing are specified by the suppliers of the base material. In combination with Becker&Müller’s many years of experience, this is used to create the process data set (the so-called “recipe”) individually for all materials and panel sizes. The standard procedure provides for a process run of the multilayers in the heating press, followed by defined cooling under maintained pressing force in the cooling press. In addition to standard PCBs, the focus at Becker&Müller is increasingly on special types for special applications, reveals Janik Becker: “For example, a customer needs PCBs for his special application on which solid ceramic blocks are pressed for thermal shielding. Of course, this is not done in the standard process.”

The downstream cooling process in particular always presents a challenge – technologically and in terms of production. “Heating and cooling presses must be optimally coordinated in terms of timing, and waiting time to reach different starting temperatures should also be avoided,” explains Janik Becker. As managing director of the experienced family-owned company, he and his team have in-depth expertise in multilayer production. “Our new heating press is a response to increased volume requirements, but also an important building block in the future orientation of our process infrastructure.”

The new LP125-2-VK vacuum chamber press from HML Haseneder Maschinenbau e.K. is the second of its kind at Becker&Müller. Complementing the existing HML heating and cooling press, it increases productivity by at least double. Formats up to 540 x 650 mm can be pressed in two press chambers, with a pressing force of 4 to 125 tons (40 – 1,250kN). The loaded press packs each hold several m² of panels of identical base material per chamber. “Previously, this was exactly our bottleneck,” clarifies the managing director. “With the new line, we have been able to increase our capacities by more than 100% – and still have room for improvement.” Increased pressure accuracy including temperature control ensures that all parameters are always in view and are recorded without gaps. “This continuous traceability is also a strong argument for our customers,” Becker lets us know. An equally strong argument for the environment of the electrically heated and water-cooled press: The heated cooling water is used to heat the company’s own premises by means of heat recovery – for added sustainability.

With the integration of the new heating press, the production processes were also realigned. One of the central factors in this process optimization of multilayer production at Becker&Müller is a new handling system. This is used to transport the multilayers from the layering station to the presses. With eight compartments for press packs, this not only offers more capacity, but is now also integrated into intelligent processes, for example by automatically approaching the press chambers.

For this purpose, a new, completely integrated control system for the entire multilayer production process has been introduced. Instead of a separate control system for each press, as was previously the case, all three are controlled via a central control system. “The end-to-end connectivity makes us faster and increases our process reliability. The press capacity can be adapted precisely and just-in-sequence to the capacity of the manual layering of the multilayers as well as the availability of the cooling press, waiting times are eliminated. This means, for example, that we can keep packages at a constant temperature in the heating press until the cooling press is free,” says Becker. “In addition, human error is minimized and overall handling is simplified. The efficient layout within our infrastructure allows us to achieve a significantly higher level of performance with smaller spatial dimensions.”

Another advantage of process automation is that the final pressings, including the heating and cooling process, can run automatically after the end of the shift. “The next morning, we can then start drilling the multilayers right away. The interaction of the three presses with the drilling machines, which also work autonomously in the ghost shift, makes it possible to minimize WIP or delivery times.”

Anyone who thought that the new automated processes at Becker&Müller would now make employees superfluous is proven wrong. “The opposite is the case,” Janik Becker is pleased to report. “Thanks to the new curing press, along with the increased connectivity, we can produce faster and therefore more – which also means more work in upstream and downstream processes. For this reason, we even had to double our staff in the area of multilayer production.”

Another interesting detail that says a lot about the company’s philosophy is that the temperature spectrum of the new line extends up to 400°C: “Actually, that’s much more than necessary,” explains Janik Becker. “For pressing multilayers, a temperature range of up to 300°C is usually sufficient. However, we deliberately want to keep all options open for the future, for example for special materials or new processes – in other words, precisely the special solutions for which we at Becker&Müller have been known for many years.”