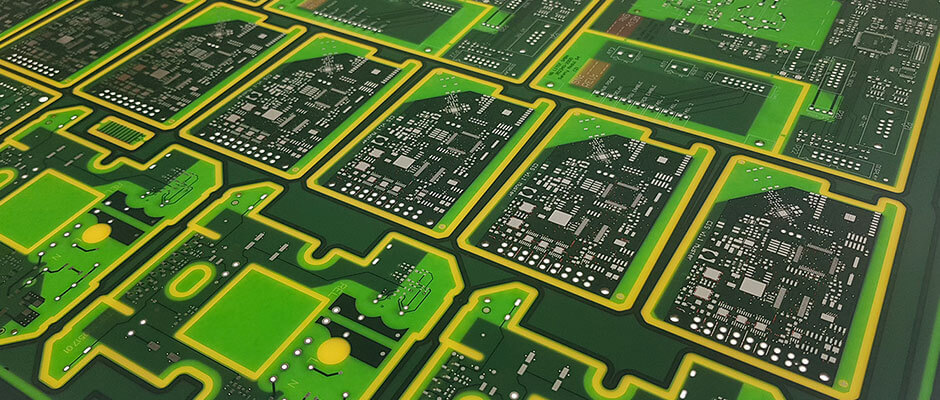

As a cost-effective and fast alternative for PCB in small series, we offer our customers the special PCB-Mix. With this production method multiple orders from different customers – with the same copper thickness and layer build-up – are placed and manufactured together on one production panel. The available specifications of the PCB are more narrowly defined in the PCB-Mix. By that, costs of material, setup and handling can be reduced. The design rules and the available PCB-Mix services (see table below) are to be observed.