Ordered. Delivered.

The fastest way to the perfect circuit board is via our PCB EXPRESS-SERVICE.

Home > Technology

Technology and quality of our circuit boards are among our highest demands. To be constant on to produce at the highest level and also to meet the high technological demands, Becker & Müller has a modern machinery, plant and equipment park. This park is always optimized and kept up-to-date through continuous investments. The same applies of course to the manufacturing processes. Last but not least, it is the joint development together with the customer and their requirements that serve as innovation drivers and reveal optimization potentials.

Quality control accompanies the entire manufacturing process of the PCB. Our test standard is the IPC A-600 class 2 – of course, tests according to the acceptance criteria of class 3 are also possible. Even during production, the circuit boards are subjected to various control and through the following measurements or tests, depending on customer requirements:

| AOI (Automatic Optical Inspection) | standard |

| Layer offset control (automatically when registered by CNC machines, manually x-ray examination) | standard for multilayers |

| E-test (electrical test) | standard for multilayers optional ≤ 2 layers |

| Impedance control | optional |

| Preparation and evaluation of micrographs | optional |

| Initial sample inspection | optional |

| Mechanical tolerance (dimensions of contours as well as position of holes to traces respectively pads) | optional |

The base of quality and precision is – in addition to qualified employees and highly developed processes – our state-of-the-art machinery and plant park. Some highlights of our production are:

In photo technology, we rely on an LED-DI direct exposure unit from Swiss Printprocess AG. Direct exposure has numerous advantages for prototyping. It guarantees a high quality of the PCB thanks to the highest precision and manufacturing accuracy. The capability to expose extremely filigree traces in combination with the automatic alignment of those layouts to the panel respectively its drilling pattern creates its own standards in quality.

Because direct exposure does not require any film – beside energy and the use of chemicals – above all, time can be saved and flexibility can be increased. In connection with the industry 4.0 ideas, it is possible for Becker & Müller – thanks to the shortest response time, fast product changes and highest precision – to respond to customer wishes or requirements and nevertheless to guarantee the highest production speed.

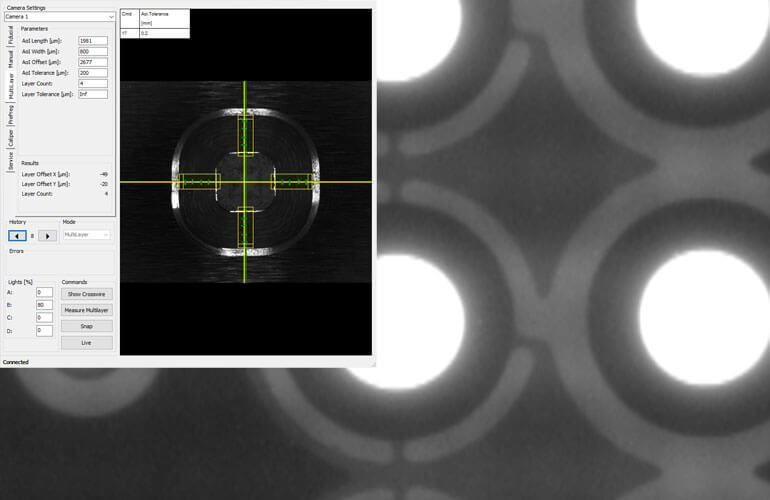

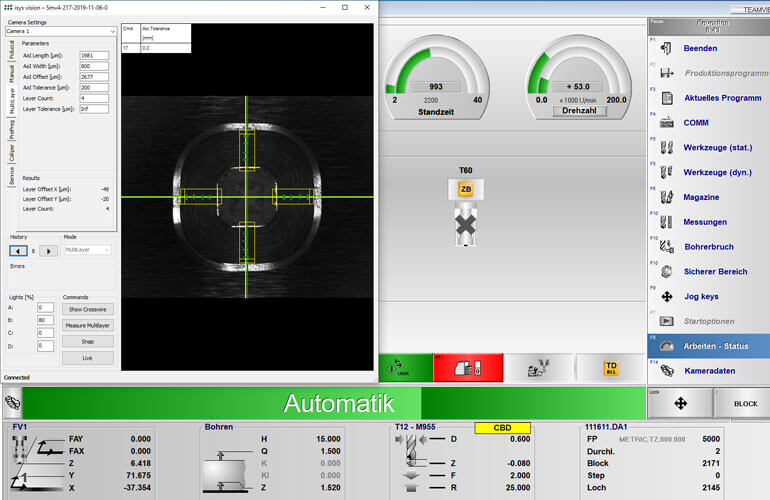

Our multilayer production is supported and supervised by a specially self-programmed software. This determines, using camera registration data, the layer offset or the moving away of the pressed multilayer. Corresponding correction values are then calculated. These are used for compensation in the subsequent drilling and exposure process, in order to optimally adapt the drilling and traces of each panel to their inner layers. Together with an layer offset check – using an x-ray machine – after the drilling process, the occurrence of possible electrical faults on the PCB can be considerably minimized.

Our CNC drilling and milling machines are equipped with a camera registration system which detects registration marks on the frame of the panels or on the individual circuit board itself. In this way, the software of the CNC machine compensates for any position deviations respectively fits drillings and millings to the traces or to the connection pads.

In connection with process-optimized tool parameters, compliance of mechanical tolerances of < 20 μm (in terms of dimensional accuracy and position accuracy between drilling/milling and traces) is made possible.

Using an optical measuring machine – a CNC-video-measuring-microscope – compliance with the required tolerances can be checked and measurements protocols are created.

Pulsplating describes a special copper plating process for galvanic copper construction. The aim is to achieve a layer thickness distribution that is as even as possible. This is particularly important for our PCB-Mix (because of the inconsistent copper distribution on the various PCB on one panel) and generally beneficial for holes with a large aspect ratio.

With pulsplating, a galvanic rectifier applies a positive followed by a temporal shorter but significantly higher negative DC voltage to the PCB panel. This makes the copper areas, which have a high current density, passive and consequently less copper is built on.

The fastest way to the perfect circuit board is via our PCB EXPRESS-SERVICE.