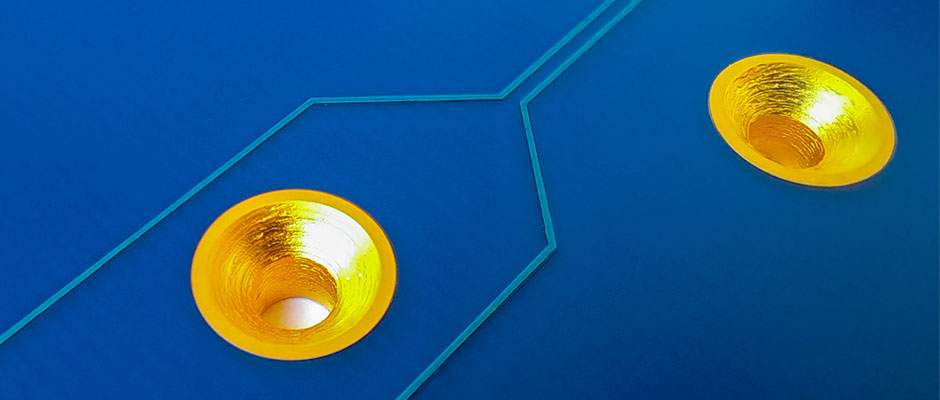

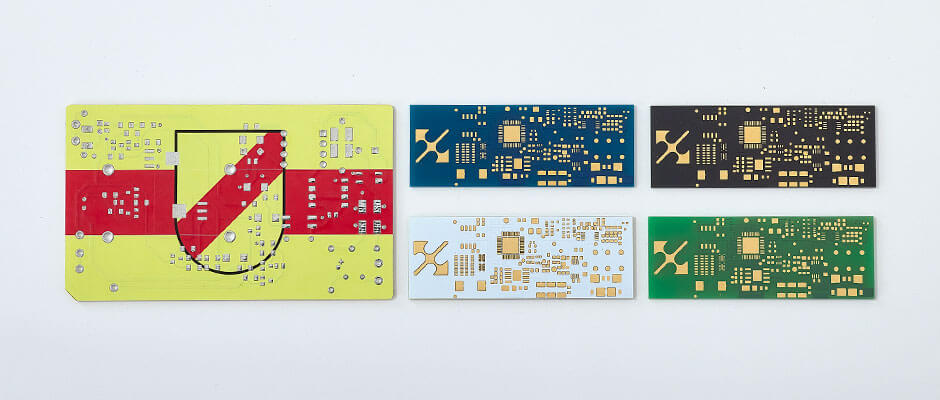

In addition to the standard colors green, white and black, solder masks are on request also available in other colors such as blue, yellow and red.

Silk screen, respectively assembly printing, can be applied in the standard colors white and black. Other colors are also possible on request.

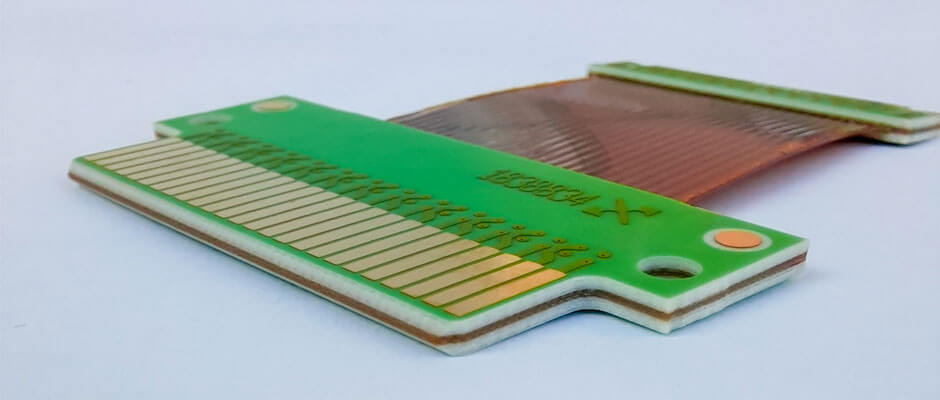

As an alternative or in addition to the solder mask, the surface of the circuit board can be covered and so protected by a coverlay, respectively a cover foil. These special masking films are resistant to abrasion and exhibit dielectric strength and therefore, according to IPC – in contrast to solder mask – to be used as an insulator.

On request, selected areas of the circuit board can be covered with a special peelable mask – a so-called bluemask. These areas are protected during the soldering process, after that the bluemask can be easily removed without leaving any residue. The aim is to enable a temporally staggered soldering of different areas of the PCB.

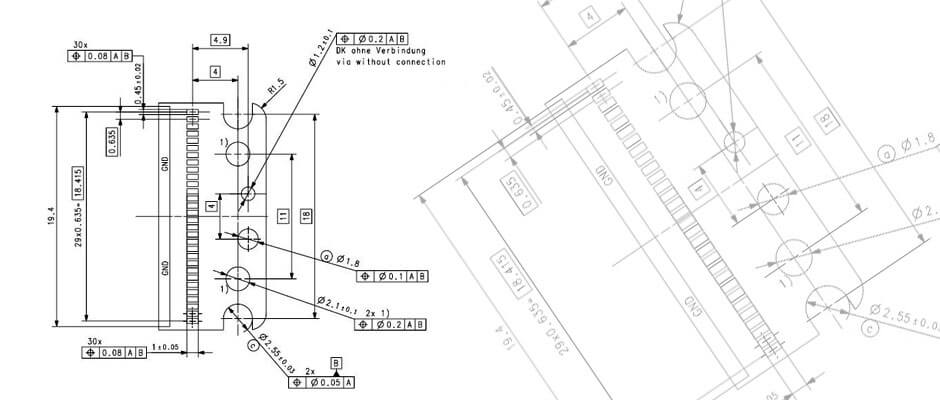

In the plugging process, vias are sealed with a dielectric. Optional the surface of the filled hole can also be metallized. Plugging can be used with conventional vias as well as with buried vias. The advantage lies in the design optimization of the circuit board layout by the possibility of using the sealed holes as a solder pad or as a landing pad for blind vias.