Impedance-controlled PCB

Home > PCB > Special types PCB > Impedance-controlled PCB

Impedance-controlled PCB

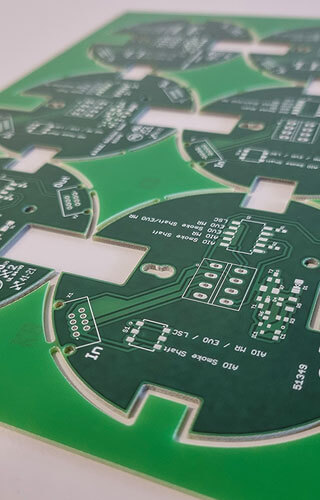

Impedance-controlled PCB are used at high frequencies and steep switching edges to ensure signal integrity. Because through reflections the signals can be superimposed resulting in sporadic and non-reproducible errors

and thus can lead to unreliability of the entire assembly. With Becker & Müller you can rely on an experienced specialist in manufacturing of impedance-controlled PCB.

How are impedance-controlled PCB made?

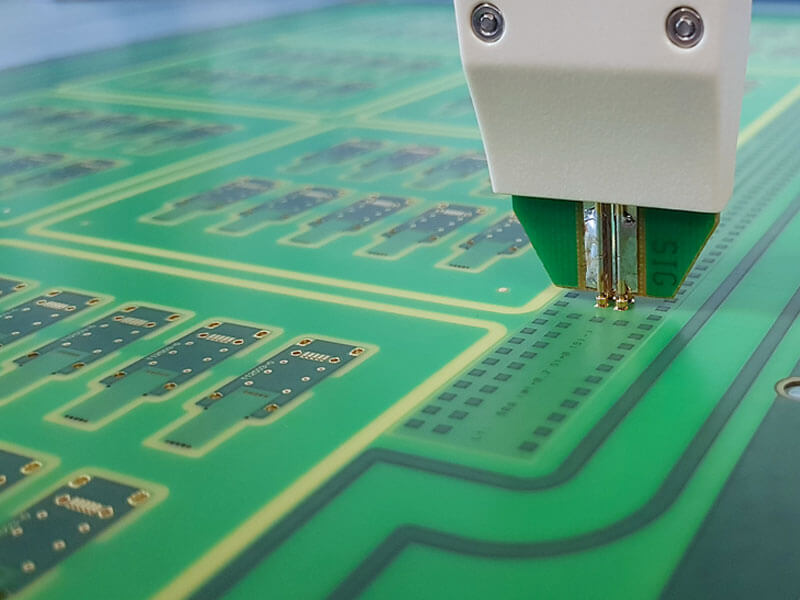

In order to counteract the above described capacitive effects the desired parameters – such as trace dimensions, layer structure or base material – are checked and if necessary adjusted using a special software from the market leader Polar instruments GmbH. That means: These parameters are manageable in PCB production. Due to high process reliability in production at Becker & Müller, compliance with the industry- standard tolerance (of the impedance) of ±10 % can be guaranteed. Narrower tolerance claims can be checked for feasibility after consultation.

A final impedance-check using representative test coupons on the PCB panel provides ultimately the exact values. The specified target impedance is compared with the measured actual values and the tolerances. The result is finally recorded in a test report.

What exactly is impedance?

The impedance of a wire or a layouted trace describes the wave resistance and significantly determines the behavior at higher and highest frequencies signals. It is therefore also responsible for the slopes of pulses of the signals. A matched impedance guarantees less loss and less reflection of a signal.

Specialist for your requirements for 37 years

Our PCB special types

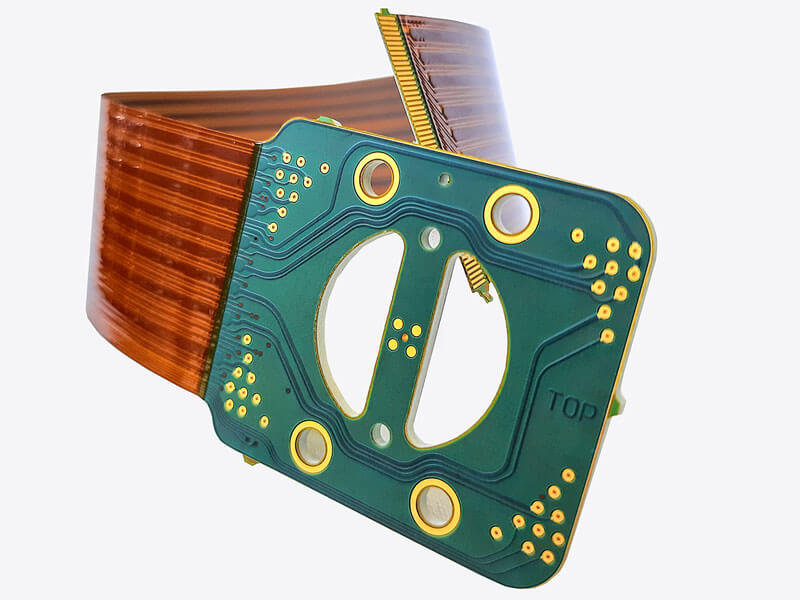

Rigid-flex and semi-flex

Rigid-flex PCB are used when the PCB in the operation is exposed mechanical movement or vibrations, also if spatial conditions do not allow any other solution.

Becker & Müller is one of the specialized manufacturers of rigid-flex and semi-flex PCB and with this development competence we like to already be available for our customers in the development phase.

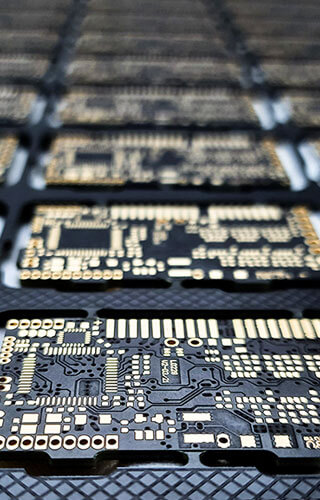

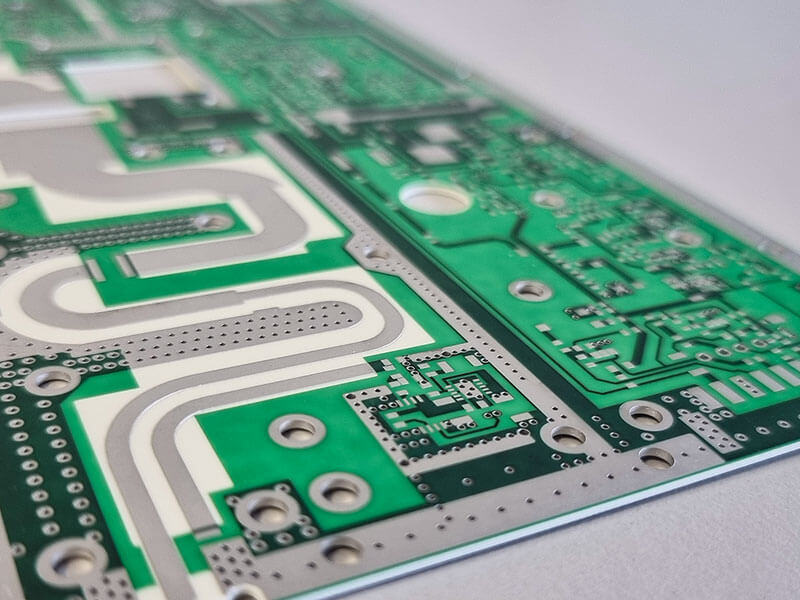

High-Frequency

High-frequency PCB (HF) are used wherever fast signal flows and thus high transmission frequencies are required. In order to ensure the integrity of the high-frequency signal flows at the highest possible frequency, the permissible parameters must be precisely determined and implemented. We at Becker & Müller are your competent manufacturer and development partner in this regard.

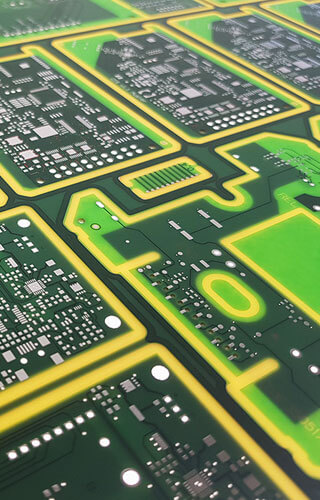

Impedance-controlled

Impedance-controlled PCB are used at high frequencies and steep switching edges to ensure signal integrity. Reflections can cause signals to superimpose, which can lead to errors and unreliability of the entire assembly. Becker & Müller is your specialist for the production of impedance-controlled PCB.

High-TG

Compared to standard FR4 materials, high-TG materials have a higher temperature resilience. These materials are used wherever the PCB is exposed to particular temperature or current loads and a higher continuous operating temperature is required for the reliability of the PCB.

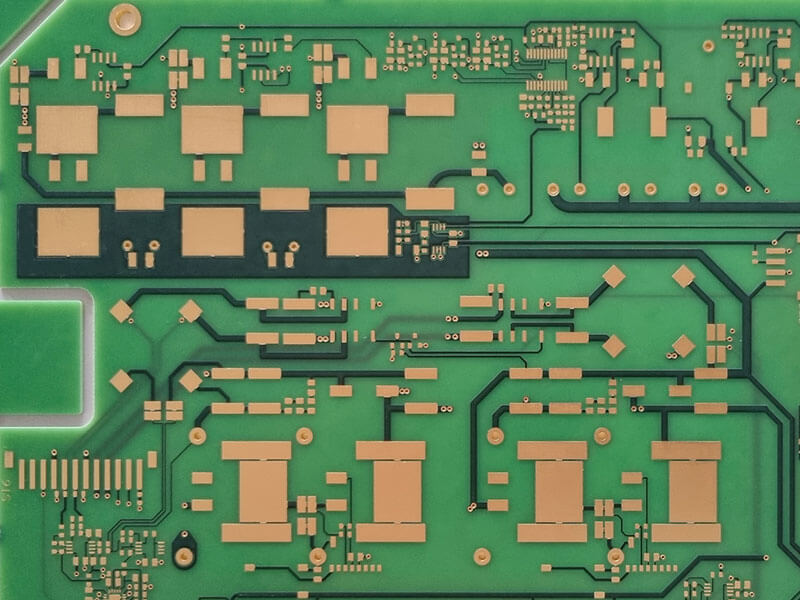

Thick-copper

The accommodation of power electronics and the associated extremely high current intensities require special specifications of the carrier circuit boards. We at Becker & Müller have customized solutions for the production of high-current/thick copper PCB.

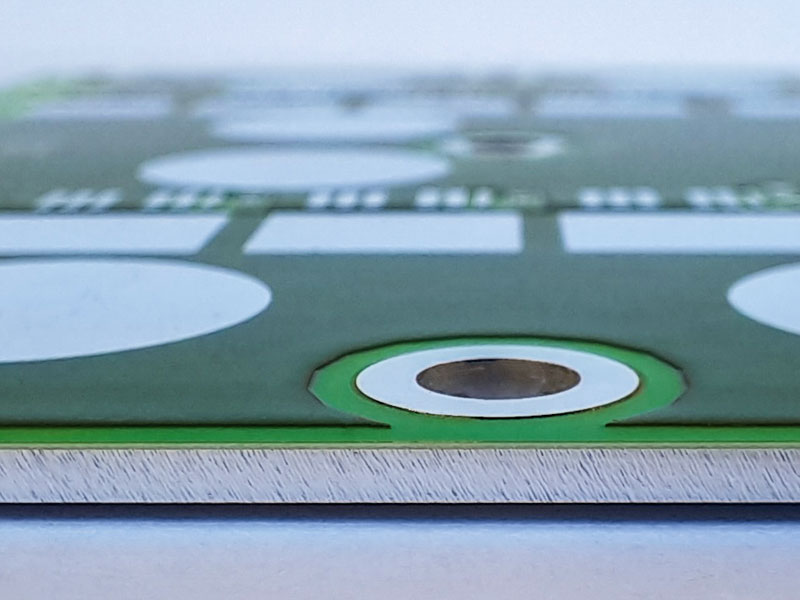

IMS PCB (aluminum core)

Aluminum core PCB – also known as IMS (Insulated Metallic Substrates) – are used for mechanical loads, but primarily for thermal loads. The core of the PCB consists entirely of aluminum and is separated from the conductor pattern by an insulation layer.

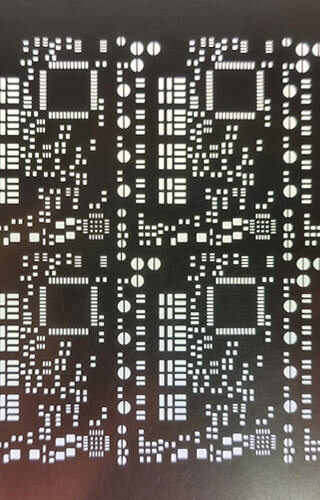

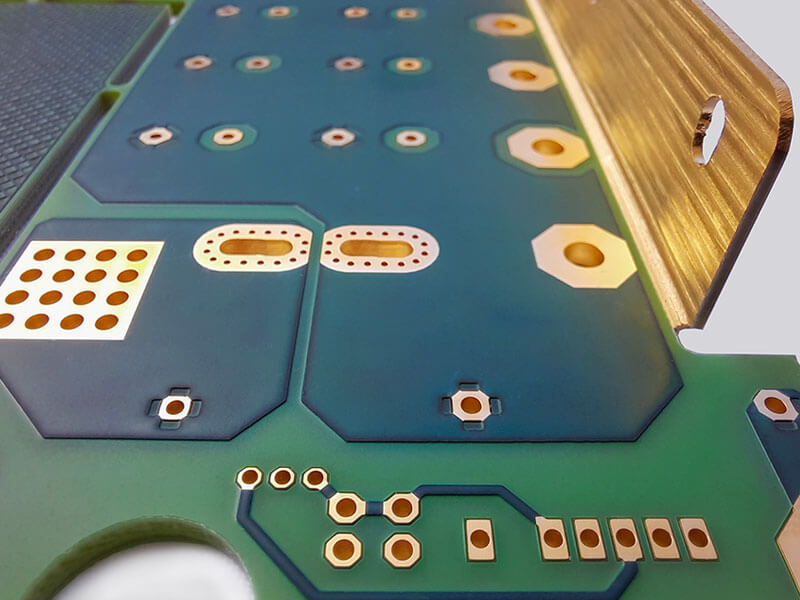

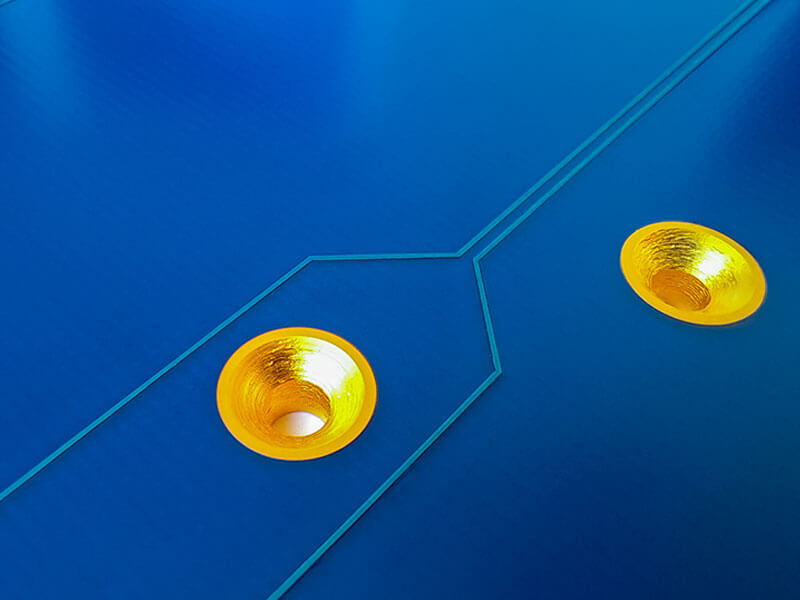

Special Service PCB

Edge metallization (PTH-contour), special contours, countersinks and depth millings, blind vias, buried vias, plugs, special surfaces or colored solder masks, silk screen, coverlay and bluemask, plugging and more: We at Becker & Müller are the ideal manufacturer and development partner when it comes to very special types of PCB.