PCB

Prototypes

individual

PCB-production

from specialist

Your PCB prototype: Manufactured by Becker & Mueller

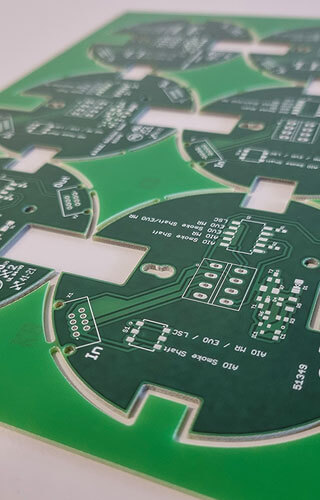

Prototyping is increasingly playing a central role in the European PCB industry. With Becker & Mueller you have the perfect manufacturer for your PCB prototype: As an experienced family business with 100% in-house production, quality, flexibility and the shortest delivery times have always been our trump card: We make this experience and expertise in the field of sophisticated PCB manufacturing your added value when it comes to your individual PCB prototyping.

What makes Becker & Mueller the ideal manufacturer of printed circuit board prototypes?

A large part of the printed circuit boards used in industry are standard and mass-produced. We at Becker & Mueller take a different approach, and have done so for decades! As a highly specialized PCB manufacturer, we have focused on the development of “special” PCBs: special types, prototypes, samples, special solutions, customer-specific and in the shortest time possible.

Uniquely flexible, uniquely fast – with Becker & Mueller as a prototype manufacturer of printed circuit boards, you rely on flexibility that is unique in the industry in terms of workflows and machinery. This means that we can produce your PCB prototype in batch size 1 and small series. In addition, there is the proven express service from Becker & Mueller, which literally makes the impossible possible: No one is faster than us!

The 100% in-house production in combination with the high-mix, low-volume strategy make Becker & Mueller the optimal development partner for the production of PCB prototypes.

We have what you need!

Sample and small series

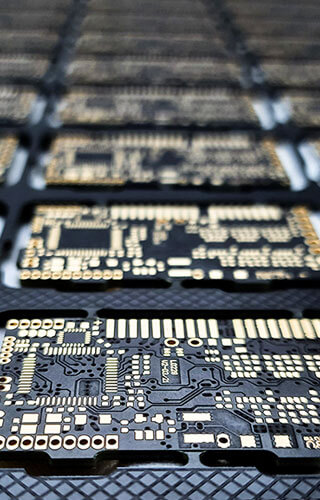

We deliver 1-layer & 2-layer PCB, mulitlayer up to 20 layers, rigid-flex, HF-substrates, special types… And that already in smallest editions.

Express-Service

We deliver your desired PCB in record time and guaranteed on time: Experience the speed and quality of Becker & Müller.

Highest quality - Made in Germany

Our modern machines & plants guarantee first-class quality and precise manufacturing – no matter if simple or complex product requirements.

Does Becker & Mueller also provide support in the development of the PCB prototype?

Yes, of course. With our decades of experience and our high-performance machinery and equipment, we are your reliable partner not only as a manufacturer of PCB prototypes. We are also at your side as a development partner in the run-up to and during the manufacturing process as well as afterwards.

At Becker & Mueller, you are in the best hands in all process phases of PCB prototyping:

- Support in development with regard to

feasibility / implementation or production /

Alternatives of your PCB prototype -

Flexible planning and production of PCB prototypes

prototypes; possibilities of the machine park

can be exhausted -

Fast subsequent delivery or fast implementation

of modifications of the PCB prototype

How long does it take to produce a PCB prototype?

The manufacturing time of the prototype of a PCB depends on the type or the structure, i.e. the manufacturing complexity. Due to our decades of expertise in PCB prototyping, we at Becker & Mueller can offer our customers an extremely fast production time – and of course in top quality “Made in Germany”.

Experience values for the production of a PCB prototype can be given as follows:

- Depending on type and layer structure double-sided and

ML from 1AT (rigid-flex 5AT) in express service - Standard delivery time 5AT double-sided, 6AT ML,

10AT flex - SMD stencils from 6h; standard LZ 6AT

- if data is delivered before 9:00 am, the current day

current day counts as production day

Specialist for your requirements for 30 years

Any questions? We answer:

As one of the leading manufacturers of special printed circuit boards, special types, prototypes and samples we at Becker & Mueller offer a high range of options for PCB prototyping:

- FR4, high-Tg, HF, flex and IMS materials are permanently in stock in various thicknesses and layer thicknesses;

comparable material properties to desired manufacturers in stock;

others on request - our standard materials:

- FR4 & high-Tg: KB, Nanya, EMC, NPG

- HF materials: Rogers 4000 series

- Flex materials: DuPont Pyralux AP series

- IMS materials: EM-MP

- Other and special materials on request

Of course, all design requirements are also or especially implemented during prototyping: especially in this area, we at Becker & Mueller are characterized by an extremely high flexibility and speed.

With our deep and long-standing expertise, we are also happy to provide advice in advance and during the DFM-process of PCB prototypes.

No. A central motto of Becker & Mueller is: “Anyone can do simple – we are the specialists for complex PCBs.” In concrete terms, this means for the production of a PCB prototype: We manufacture from batch size 1.

A subsequent (small-)series production can be carried out with identical technology. Here, too, as an experienced manufacturer, we are happy to be at your side.

For subsequent series production, we are happy to recommend series manufacturers who are comparable to prototype production in terms of material selection and production technology.

The unit cost of a PCB prototype depends on the required technology, materials and number of pieces.

At Becker & Mueller, you can rely on the same quality for the production of PCB prototypes as for samples and small series: We give everything to produce only the best for our customers! The fact that we are ISO 9001:2015 certified is only one part of a comprehensive quality assurance.

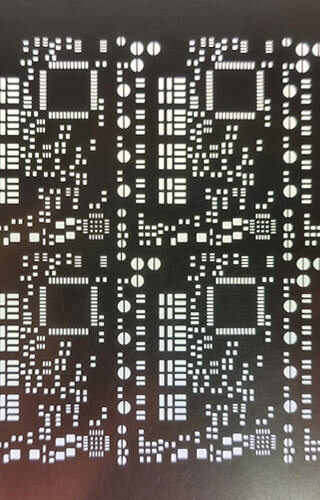

Our quality standards for the production of PCB prototypes:

- Test standard according to IPC A-600 class 2 (optionally also class IPC A- 600 3 possible).

- 100% AOI for outer and inner layers

- 100% layer offset control for multilayers

- 100% E-test (for multilayer, optional for double-sided PCB)

- Impedance control optional

- Initial sample test report optional

- Micrographs optional

- Test report mechanical tolerances optional (via CNC video measuring microscope)

In order to be able to offer our customers a maximum range of services, we work together with external assemblers in the German region if required. Delivery times by arrangement (depending on quantity and component availability).

At Becker & Müller, we stand for the highest level of individuality in the production of PCB prototypes. This also means being in close, direct and fast contact with our customers:

- by telephone

- by mail

- via online form

- in person

When exchanging data on designs for the production of PCB prototypes, we are guided by the wishes of our customers and receive and/or send data

- by mail

- via the customer’s cloud (e.g. Sharepoint)

- via USB stick

One of the central premises of Becker & Mueller’s corporate philosophy is speed, of course always under the condition of best quality. Our claim and promise is: Nobody is faster than us! Of course, this also applies to the production of PCB prototypes:

- Depending on the respective technology, complexity and production start of the PCB prototype from 1AT.

- Delivery time for assembled boards on request

Anyone who offers the greatest possible individuality in the production of special printed circuit boards, as we do at Becker & Mueller, must of course also always personally support their customers with expertise and advice. And that’s exactly what we do, of course, when it comes to the production of PCB prototypes:

- If you have any technical questions, we are always happy to provide advice by phone, e-mail or in person.

- Design adaptations from a technical and production point of view are made in consultation with the customer. In the case of specific design or layer structure and layout questions, we work together with an external layouter. We are happy to act as a link and provide support during the consultation process.

- For particularly demanding PCBs, we develop solutions in production together with the customer.

- Of course, we also offer our well-known express service for prototyping.

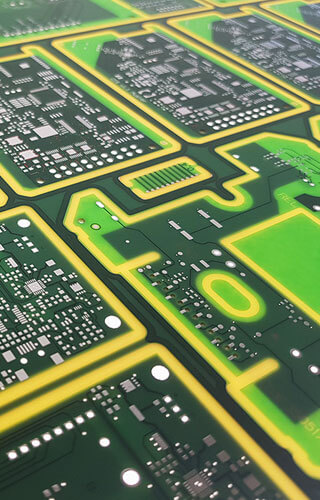

The production of PCB prototypes in small and very small quantities from batch size 1 is always challenging in terms of the efficiency of the production process. Such small runs are always in contrast to mass-produced goods.

As a specialist for special types, samples and prototypes, Becker & Müller has extensive experience in dealing with production processes in such small quantities. This includes, in particular, production in the PCB mix.

In PCB mix production, PCBs from different customers with identical specifications (such as layer structure, copper layer thickness and final surface) are produced on one manufacturing blank. This reduces both the one-off costs incurred and the setup costs – a cost saving that is passed on directly to the customer.

YOUR MESSAGE TO US

The fastest way to the perfect PCB is via our PCB EXPRESS SERVICE.